Badge production processes are generally divided into stamping, die casting, hydraulic pressure, corrosion, etc., in which stamping and die casting are more common. Color treatment is divided into enamel (Jingtai Lan), imitation enamel, paint, dripping, printing, etc. The material of the badge is generally divided into zinc alloy, copper, stainless steel, iron, sterling silver, pure gold and other alloy materials

Pressing badge: The materials used in general stamping badges are copper, iron, aluminum, etc., so it is also called metal badge. The most common is copper badge, because the copper is relatively softened, the most clearer lines are pressed, and the iron emblem is second. The price of the corresponding copper is also more expensive.

Die cast badges: Die cast badges are usually used in zinc alloy materials. Due to the low melting point of its zinc alloy material, the mold is injected into the mold after heating, which can make complex and highly difficult relief hollow badges.

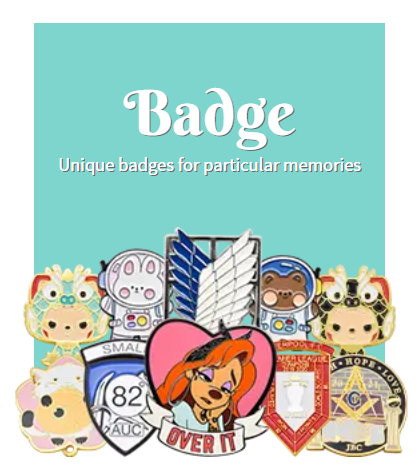

Yingyao Craft Gifts are committed to providing customers with one -stop customized services, from creative design to manufacturing, and provide you with deep interventional service models with products such as badge customization, medal customization Coins, keychain, refrigerator stickers, coins, etc. You only need to put forward the demand, we can deliver on time. Welcome to consult.

Post time: May-17-2024