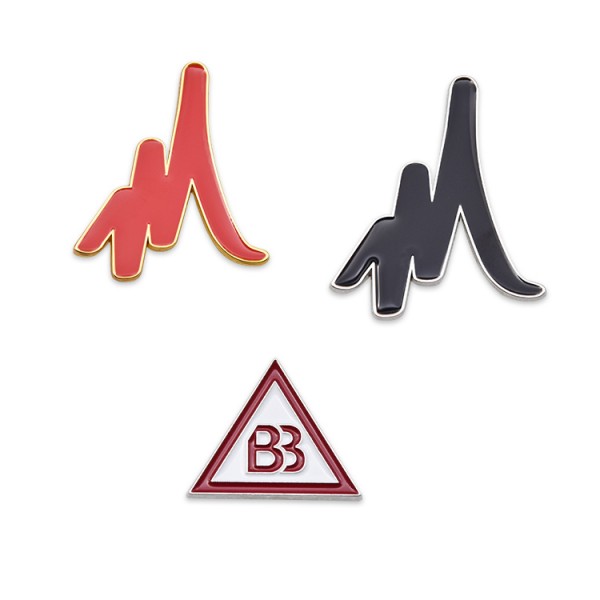

Bestseller Custom Glitter Diamond Shape Lapel Pins

* Bestseller Custom Glitter Diamond Shape Lapel Pins

Customized Badge Description

|

Material |

Zinc Alloy, Brass, Iron, Stainless Steel and so on |

|

Craft |

Soft Enamel, Hard Enamel, Offset Printing, Silk Screen Printing, Die Struck, Transparent Color, Stained Glass and so on |

|

Shape |

2D, 3D, Double Side and Other Custom Shape |

|

Plating |

Nickel Plating, Brass Plating, Gold Plating, Copper Plating, Silver Plating, Rainbow Plating, Double Tone Plating and so on |

|

Back Side |

Smooth, Matte, Special Pattern |

|

Accessories |

Butterfly Clutch, Badge Pins |

|

Package |

PE Bag, Opp Bag, Biodegradable OPP bag and so on |

|

Shipment |

FedEx, UPS, TNT, DHL and so on |

|

Payment |

T/T, Alipay, PayPal |

Keychain Tips

The general process of badge making has the following 7 steps:

First: design the style and pattern of the badge. The design can be designed by the customer page can be designed by the manufacturer, the customer design does not meet the processing requirements of the unreasonable changes for the customer to confirm, generally with CDR file.

Secondly: make the badge mold, the good badge with CDR into the fine engraving machine program for mold carving, mold after carving to heat treatment of the mold, to strengthen the hardness and durability of the mold.

Again: badge pressing, the mold will be installed on the punching machine or hydraulic press workbench, the pattern of metal materials.

Fourth: badge material punching material, first do a good badge shape knife mold, the product according to its shape, with a punch to the product down

Fifth: badge surface polishing, badge after cutting off the shape of the stamping burr, improve the smoothness of the badge surface.

Sixth: to carry on electroplating to the badge. According to customer's requirements, badges can be plated with gold, silver, nickel, copper, etc

Seventh: pack the badges according to the customer's requirements and send them to the customer by consignment or logistics.

1200_013.jpg)